MANUFACTURING SERVICES

New product development as per customer requirements using CAD modules

Reverse Engineering concepts

Research and Engineering Devlopments

Contact us

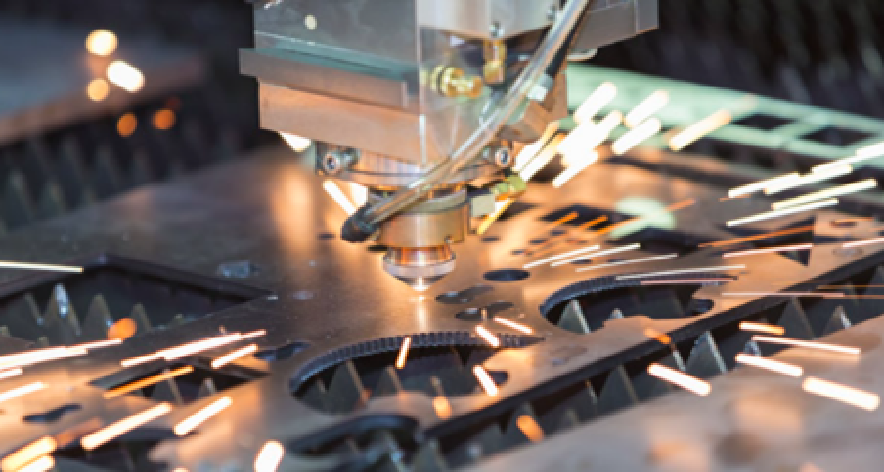

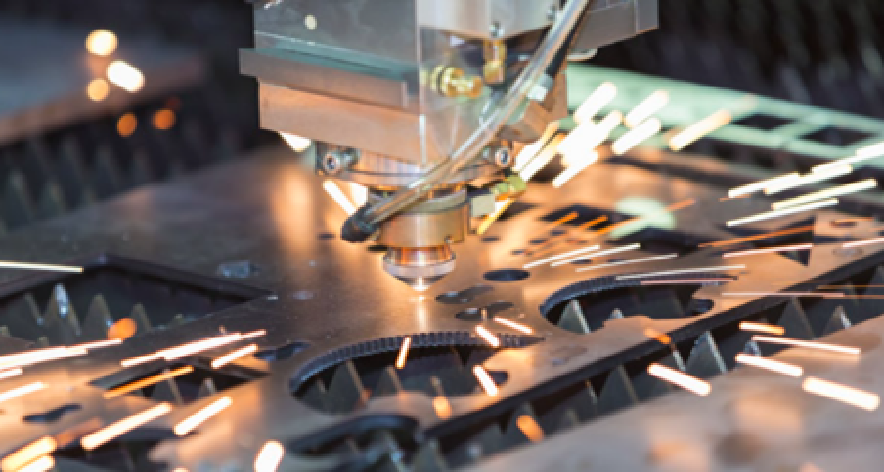

Fiber laser cutting tools and machinery involve to cut several profile of different unique material (CRS, HRS, Aluminium, Stainless Steels, & Copper) with precise tolerance cutting edges

Machine Capability:

Working Sheet Size : 4ft x 8ft

Cutting Speed : 0.8 m/min

Positional Accuracy : 0.03mm

Thickness Range :

Mild Steel – Max. 12mm thk.

Stainless Steel – Max. 6mm thk.

Aluminium - Max. 4mm thk

Air Bending process involes to perform the desired sheet metal bending profile as per the customer required precise tolerance

Standard and customized bending tools and dies where used to achieve perfect bending angles and bending radius

Machine Capability

Working Length : 3 meter

Position Accuracy : ± 0.05 mm

Tonnage : 170 Ton

Bend Thickness : Max. 12 mm

Capable on Conventional Welding process involve both TIG and MIG, RSW Resistance Spot welding of various metal like mild steel, Cold roll Steel, Stainless steel, Aluminium grades

The process qualified based on AWS welding standard for the thickness range 1mm ~ 12mm of sheet metal and structural frame

Machine Capability:

We perform high-quality TIG welding with quality Miller 250 amperage equipment.

At Welded Sheet Metal Specialty with 300 amp welder for optimal performance.

DC inverter Spot welder thickness range 0.8mm to 3mm thk. of Aluminium, CRS, SS sheet metals

We are capable on several assembly methodology of clinching installation, Riveting assy, torque Screw assy and several electronic assy.

Machine Capability:Haeger brand with 6 tonnage capacity of pressing force max install M8 Pem nuts and studs

Contact us

Powder coating, Wet painting, Plating, chemical conversion and other finishing prcess are managing by tied up with qualified subcontractors

Contact usDISCOVER HOW WELL ENGINEERED PRODUCTS CAN SUPERCHARGE YOUR OPERATIONS AND BOOST YOUR BOTTOM LINE.

GET IN TOUCH