COMPRESSORS

"Monozukuri" literally means Production or Manufacturing in Japanese word.

But this "Monozukuri" especially has meaning of integration of prowess,

know-how, and spirit of Japanese manufacturing, which include sincere

mind, pride for the quality backed by skill, dedication and the pursuit of

innovation and perfection.

KOBELCO explores this "Monozukuri" for more than 100 years as a Japanese

lead ing compressor manufacturer, and quality of our products are for the

dedication to "Monozukuri" in the world.

Our endeavor for future technology, top quality, and for maximum customer

satis faction will not stop.

For the next 100 years...

Never ending challenge of KOBELCO just starts here.

Motor Output: 132-400kW

Discharge air flow : 19.2-66.8 m³/min

Motor Output: 45-120kW

Discharge air flow : 5.4-17.2 m³/min

Motor Output: 22-55kW

Discharge air flow : 3.0-8.1 m³/min

What's most essential value for oil-free compres sors is to supply pure, clean, oil-free air stably in any running conditions. For critical applications, such as, food and beverages processing, semicon ductor and electronics manufacturing, medicines manufacturing and more, even the smallest oil contamination never been accepted.

As a pioneer of oil-free technology with over 60 years of history, Emeraude ALE/ FE series assure safe oil-free compressed air and utmost reliability for your production.

KOBELCO has received Class 0 certification ( 1S08573-1 [-:-:0]) for (Emeraude ALE) series from international test institute called TOV which certifies the highest level of purity for qualityclassificationsof compressed air. This is one proof of KOBELCO's supreme oil-free technology.

| CLASS | Concentrated total oil(aerosol, liquid,vapor) mg/m³ |

|---|---|

| 0 | As specified by equipment user or suplier and more stringent than class 1 |

| 1 | <=0.01 |

| 2 | <=0.1 |

| 3 | <=1 |

| 4 | <=5 |

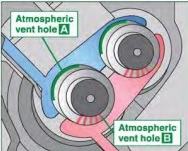

KOBELCO's proven dual vent holes design prevents oil entry in compressor chambers during long unload running

Now, brand-new chapter in the over 60

years history of KOBELCO's oil-free

technology has just started, New

generation Emeraude ALE debut.

With

ultimate specific power consumption,

supreme silence and outstanding

durability, Emeraude ALE reached new

stage in the industry.

Proudly standing

dark green elegance is the result of our

never ending challenges for technology

innovation and craftsmanship

improvement over the long history.

Pursuing the perfection, making it a

masterpiece.

By developing state-of-the-art air-ends and optimized package design, we achieved best in class specific power consumption as well as utmost durability. Here, new standard of oil-free compressors starts.

Supreme energy efficiency for the lowest possible ownership cost.

Motor power:132-400kW

Discharge air flow: 19.2- 66.8 m³/min

Ultimate Energy Efficient KOBELCO's Flagship.

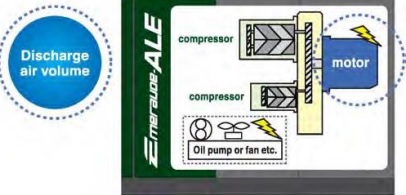

By developing state-of-the-art air-ends and optimized package design, we achieved best in class specific power consumption as well as utmost durability. Here, new standard of oil-free compressors starts.

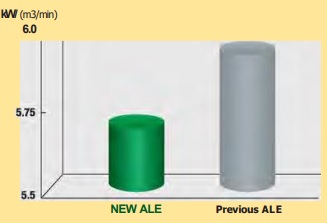

New ALE's performance is evaluated by specific power consumption as per JIS B 8341:2008 ( 1801217 Edition3 equivalent). KOBELCO places an importance on not only shaft power but also compressor's total input power including energy loss in the compressor because electricity consumption for customers is not shaft power and rated motor power but compressor's total input power.

Compared with Previous ALE: 3% Performance improvement

Specific power consumption is the new valuation standard based on compressor's total input power and discharge air volume. It shows the actual customer's energy use.

Previous valuation standard evaluated discharge air volume and shaft power separately. New valuation standard evaluate "specific power consumption" which shows energy consumption to create compressed air of 1m3/min in addition to discharge air volume. This means an actual compressor performance including fan motors and an oil pump.

KOBELCO has achieved class leading performance with specific power consumption because of newly designed rotors, reduction of energy loss and selection of high efficient components.

DISCOVER HOW WELL ENGINEERED PRODUCTS CAN SUPERCHARGE YOUR OPERATIONS AND BOOST YOUR BOTTOM LINE.

GET IN TOUCH